Industry insight

You can visualize data, create immersive reports, and share the same reports across your organization to enhance everyone's ability to make efficient decisions.

-

Complex production process

Complex production process【 Engineering Design 】Mechanical manufacturing often involves complex engineering and design processes, including computer-aided design (CAD) modeling, simulation, and prototyping.

【 Assembly and testing 】The assembly process of machinery can be very complex, requiring precise coordination and integration of various components, followed by rigorous testing to ensure functionality and reliability.

-

Supply chain management

Supply chain management【 Complex network 】The industry relies on a complex supply chain that includes numerous suppliers and suppliers, making inventory management, procurement, and logistics management challenging.

【 Global Sourcing 】Many machinery companies source components globally, which can lead to issues of quality control, delivery times, and geopolitical risk.

-

After-sales service and maintenance

After-sales service and maintenance【 Long Product life cycle 】Mechanical products typically have a long life cycle and require ongoing maintenance, support and replacement of spare parts.

【 Service efficiency 】Managing service contracts, scheduling maintenance, and ensuring the availability of spare parts can be resource-intensive and require robust system support.

-

Cost management

Cost management【 Rising cost 】Increased costs of raw materials, labor and energy could affect profitability.

【 Price pressure 】Competitive pressures often lead to lower prices, which can compress margins and affect overall financial performance.

-

Customization and flexibility

Customization and flexibility【 Customized 】Many mechanical products are customized to the specific needs of customers, which requires flexibility in manufacturing processes and configurations.

【 Production adaptability 】Being able to quickly adjust production lines and processes to accommodate custom orders can be challenging.

-

Data management and analysis

Data management and analysis【 Big Data 】Managing and analyzing large amounts of data from production processes, customer interactions, and maintenance activities can be a challenge.

【 Data Security 】Keeping sensitive data safe and protected against cyber threats is critical.

Learn more about scenario solutions

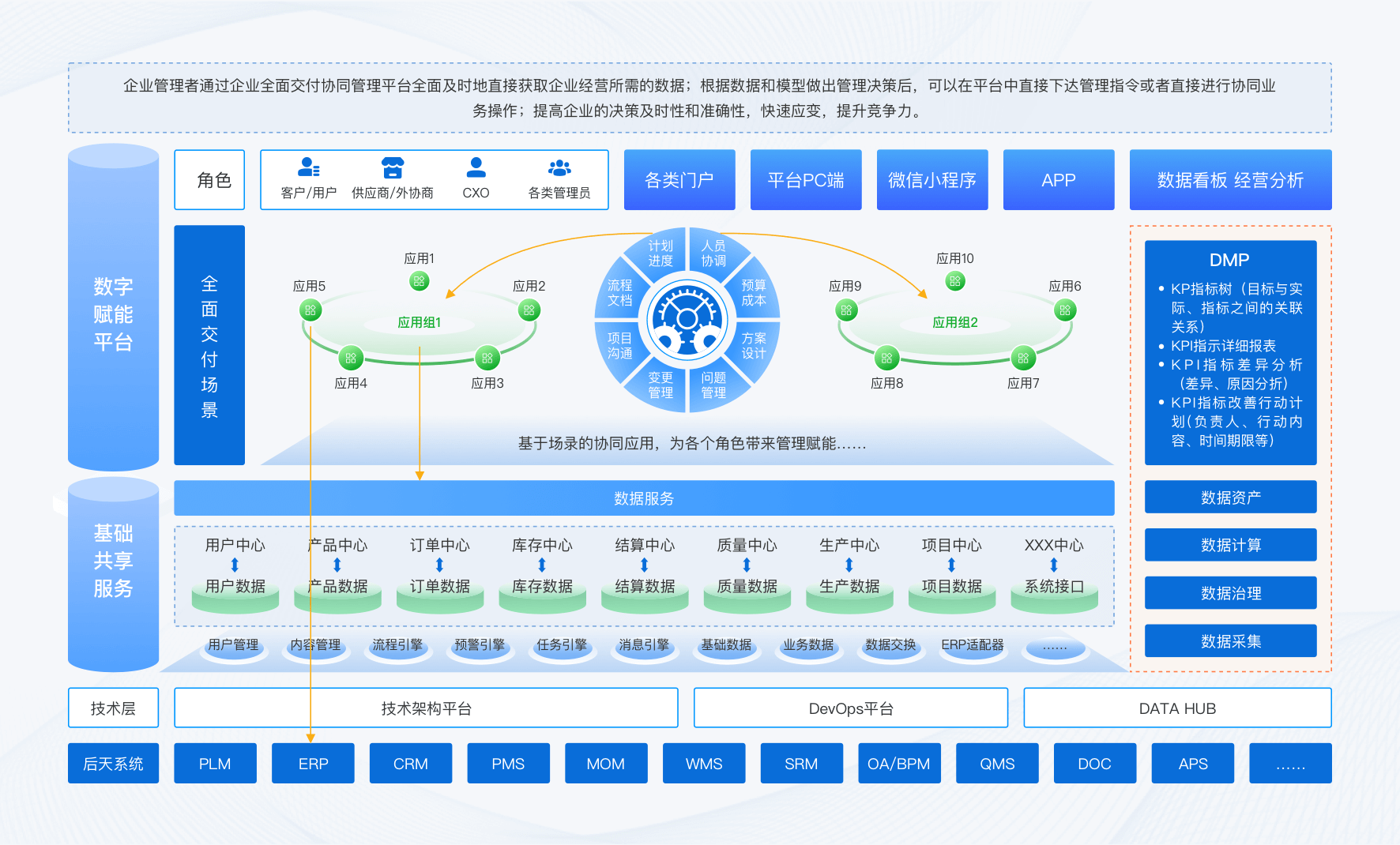

Nearly a thousand major customers digital transformation service experience, to provide customers with the process of consulting diagnosis, business combing and planning, landing work

with solutions, value creation and other end-to-end services.

-

Production and manufacturing management

【Production order】Manage production orders from planning to execution, including scheduling, resource allocation, and production process tracking.

【Bill of Materials (BOM)】Define and manage bills of material for multiple versions of mechanical parts and assemblies to ensure accurate tracking of components and materials.

【Process route】Set up the production process route, including steps, work centers, and required resources.

【Capacity Planning】Optimize production capacity and resource utilization to meet demand and improve efficiency.

-

Supply chain management

【Inventory Management】 Track and manage inventory levels of mechanical parts, assemblies and finished products, including real-time visualization and automatic replenishment.

【Procurement】 Automate the procurement process, manage supplier relationships, track purchase orders for mechanical components and raw materials.

【Warehouse Management】Streamline warehouse operations, including storage, picking, packaging, and delivery of mechanical components and finished products.

-

Project management

【Work Management】Handle work related to new product projects, including budget, cost and resource management.

【Project tracking】Monitor project progress, costs and profitability to ensure projects are on schedule and within budget.

-

Sales and service management

【Sales Order and quotation】Manage sales orders, quotes and invoices for machinery and related services.

【Customer Relationship Management (CRM)】

Track customer interactions, manage service agreements, and improve customer satisfaction.

【Service Management】Handles service contracts, maintenance and repair operations for machinery, including service requests and technician assignments.

-

Financial management and analysis

【Accounting】Streamline financial operations such as general ledger, accounts payable and accounts receivable.

【Cost accounting】Analyze the costs associated with machine production, including overhead, labor, and material costs.

【Financial Report】Generate financial statements and reports to gain insight into business performance and profitability.

【Business Intelligence】Gain insight into sales performance, productivity and inventory management with built-in analytics.

-

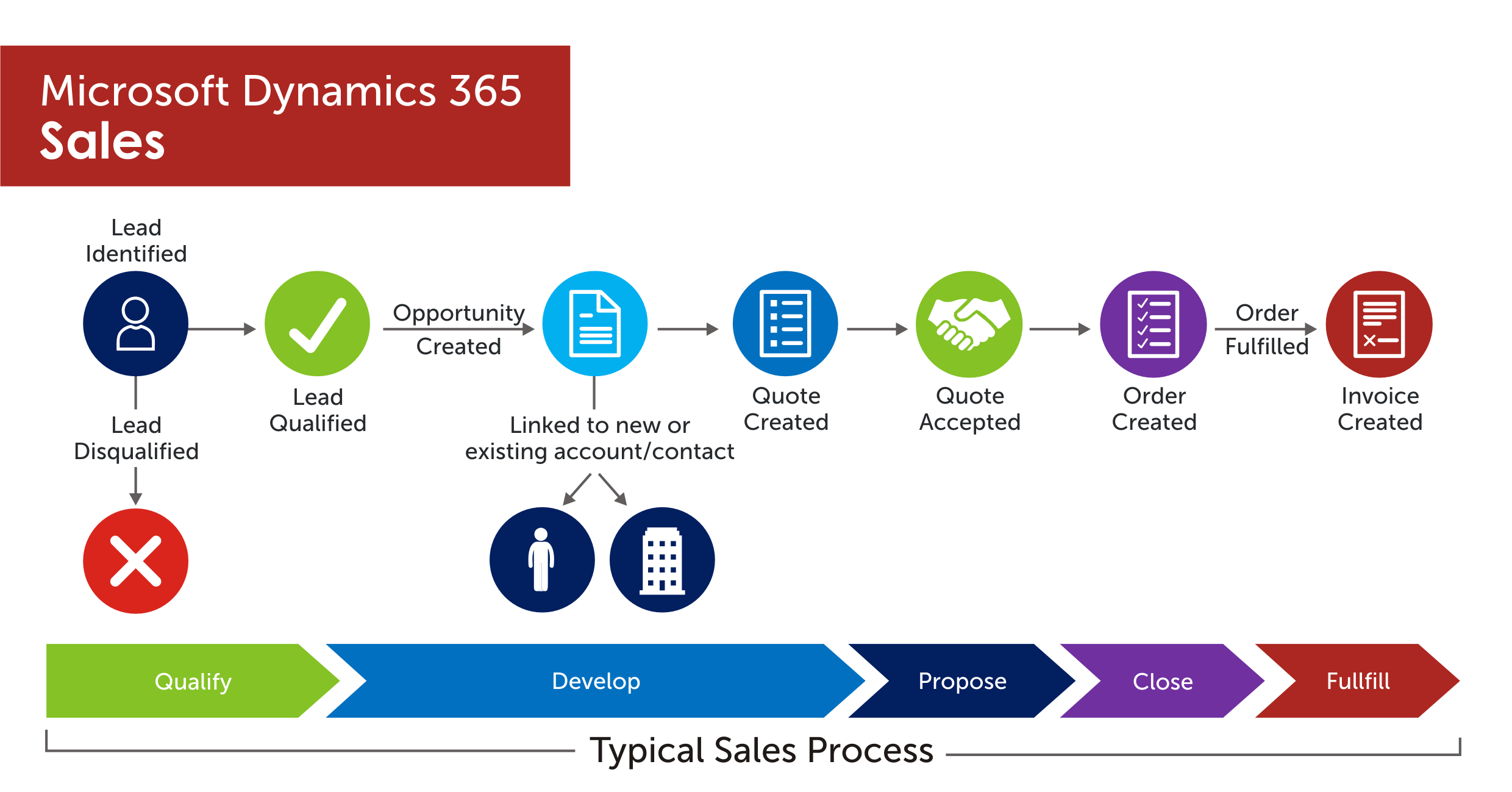

Sales automation

【Lead and Opportunity Management】Track and manage leads and opportunities through automated workflows to ensure follow-ups and conversions.

【Sales Forecasting and Insights】Use AI-powered insights to predict sales trends, prioritize opportunities and make data-driven decisions.

【Quotation Management】Easily create, send, and manage quotes for complex machine sales, including multiple configuration and customization options.

-

Customer Relationship Management (CRM)

【Customer Insight】Get a 360-degree view of your customers by integrating data from a variety of channels to help your sales team understand customer needs and preferences.

【Account and Contact Management】Centralize customer information to improve communication and relationship management.

-

Product Configuration and CPQ (Configuration, Pricing, quotation)

【Advanced Product Configurator】Support complex product configurations in machine sales to ensure accurate quotation and order processing.

【CPQ Tool】Simplify the quotation process for custom machinery by integrating CPQ tools to quickly generate accurate prices and proposals

-

Field service integration

【Service Scheduling and Optimization】Schedule service appointments, track service history, and ensure machine uptime with predictive maintenance.

【Mobile Field service】Provide field technicians with mobile tools to access customer data, service history, and product manuals to improve first-time repair rates.

-

Integration with ERP and supply chain

【ERP Integration】Seamlessly connect Dynamics 365 supply chain management and finance modules to align sales with inventory, production, and logistics.

【Inventory visualization】Ensure sales teams have real-time access to inventory levels, production schedules and delivery schedules.

Customer Success Stories

See how Radius intelligently helps traditional industries achieve digital transformation

Request Callback

Please complete the form below and we will be in touch or book a call with one of our Microsoft consultants.